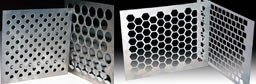

Perforated Metal Styles

- Stainless Steel Staggered Sheet in Coil

- Diamond Hole Perforated Metal Panels

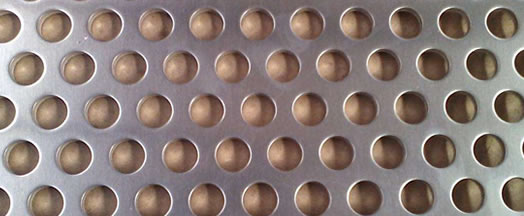

- Embossed Sheet Metal

- Slotted Hole Perforated Sheet

- Perforated Noise Barrier Panels

- Punched Slotted Tubes

- Perforated Acoustic Screen Panels

- Perforated Metal Sunshade Screen

- Perforated Metal Disc Filters

- Perforated Ceiling Panels

- Perforated Diffusers

- Perforated Ducting

- Perforated Louvers

- Checker Plate

- Round Hole Perforated Sheet

- Square Hole Perforated Sheet

- Semi-Circular Hole Metal Sheet

- Triangle Opening Metal Sheet

- Decorative Opening Metal Sheet

Perforated Materials:

- Perforated Sheet in Aluminum Powder Coated Black

- Perforated Metal Plates for Tubes

- Perforated Stainless Steel

- SUS 304 Punched Plate

- Aluminum Perforated Sheet

- Perforated Copper Sheet

- Mild Steel Perforated Metal

Perforated Metal Products

- Perforated Stainless Steel Sheets for Steam Strainers

- Perforated Stainless Steel Sleeves

- Dimple Perforated Sheet Steel Grating

- Stainless Steel Perforated Strainer Basket

- Perforated Stainless Steel Air Curtain Screen

- Perforated Screen Sheet in Stainless Steel

- Perforated Windproof Nets

- Perforated Vent Grille

- Polisher Screen

- Perforated Metal Grader Screen

- Perforated Stainless Steel Milling Screen

- Perforated Angle Bead

- Perforated Plate Sieves

- Slotted Filter Sheet

- Perforated Metal Coils

- Perforated Sheets

- Perforated Panels

- Perforated Metal Screen

- Perforated Steel Tube

- Perforated Filters

- Perforated Grilles

- Speaker Grille

- Perforated SS Tube

- Aluminum Perforated Strips

- Balustrade Panels

- Perforated Panel Railings

- Fire Escape Staircase

- Perforated Rack Panels

- Perforated Architecture Mesh

- Perforated Metal Security Screen

- Perforated Cable Tray

- Perforated Channel Cable Tray

- Checkered Tread Plate

Technical Terms:

- Perforated Metal Opening Patterns

- Applications of Perforated Sheet

- Materials Applied for Perforated Metal

- Benefits of Perforated Metal

- Calculation of Sheet Metal Weight

- Open Area Calculation

- Perforated Metal Definition

- Perforated Metal Features

- Terminology of Perforated Metal

Other Sheet Metals

Processing Machines

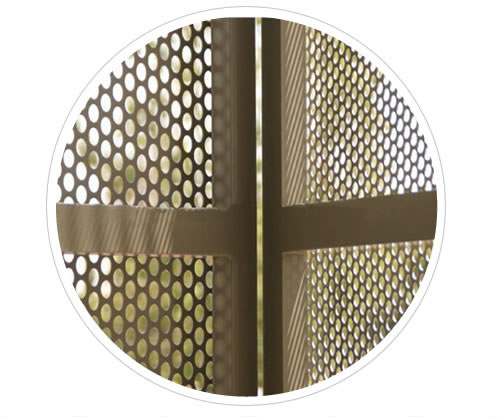

Modular Perforated Steel Shade Screen - Sun Screen Panels

Hengda perforated steel sheet can be used to fabricate sunshade screen for outdoor uses in modern style architectures. Perforated metal sunscreens / sunshades can be an integral part of a building to enhance energy saving and aesthetics looks. Accurate and decorative perforated metal sheet is the ideal material for architectural sun screens and shades with four major benefits: First, perforated sheet enjoys longest work life compared with other building materials; second, it can be fabricated into any shape easily; third, nearly maintenance free; fourth, perforated sheet can be offered in a variety of colors and finishes to suit the building style.

Modular Steel Perforated Sheet for Shade Screens

| Item No. | Description | Material |

| Modular steel sun shades structure | ||

| HD37 | Model 1 - overall size 170x404cm | Steel, Anoidzed, other metals |

| HD38 | Model 1 - overall size 170x374cm | Steel, Anoidzed, other metals |

| HD39 | Model 2 - overall size 190x404cm | Steel, Anoidzed, other metals |

| HD40 | Model 2 - overall size 190x374cm | Steel, Anoidzed, other metals |

| HD41 | Model 3 - overall size 150x404cm | Steel, Anoidzed, other metals |

| HD42 | Model 3 - overall size 150x374cm | Steel, Anoidzed, other metals |

| HD43 | Model 4 - overall size 163x360cm | Steel, Anoidzed, other metals |

Perforated sheet sun shade screen offers the following advantages:•Reduction of energy costs;

•Mitigation of heat and glare from the sun;

•A means for natural light to pass through to illuminate the interior of the building;

•Abatement of noise and wind effects;

•Privacy enhancement;

•Improvement to the aesthetic appearance of the building.

Technical Information of Steel Sheets Perforated for Metal Shades:

Materials: Various, including Stainless steel, carbon steel, brass, aluminum plate or galvanized plate.

Dimension: Modular or Customized

Perforations: Round, square, oblong, diamond, hexagonal, or special shape as customized, mainly listed as following.

Round holes 60 angle staggered center;

Round holes 45 angle staggered center;

Round holes - square centers;

Hexagonal holes;

Square holes - square center pattern;

Square holes - staggered center pattern.

Surface treating: Electro galvanized, anodized, hot dipped galvanized, PVC coated, or anodized.

Features:

1.Can be readily formed

2.Can be painted or polished

3.Easy installation

4.Attractive appearance

5.Wide range of thickness available

6.Largest selection of hole size pattern and configurations

7.Uniform sound abatement

8.Excellent wear life and durable

9.Superior abrasion resistance

10.Accuracy of size

Major Components for Modular Perforated Shade Structures: Tubes, sheets, stiffeners, columns, cylinders, etc.

Mild steel hollow tube:100x50x5mm 3mm

Steel sheets perforated: 3mm thickness. Diamond holes.

Steel stiffeners at intervals: 10x30 mm

Metallic column: 75mm, 15mm thickness fixed in reinforced concrete beam

10x30 mm steel stiffeners at intervals

Handles

Cylinder

Others.