Perforated Metal Styles

- Stainless Steel Staggered Sheet in Coil

- Diamond Hole Perforated Metal Panels

- Embossed Sheet Metal

- Slotted Hole Perforated Sheet

- Perforated Noise Barrier Panels

- Punched Slotted Tubes

- Perforated Acoustic Screen Panels

- Perforated Metal Sunshade Screen

- Perforated Metal Disc Filters

- Perforated Ceiling Panels

- Perforated Diffusers

- Perforated Ducting

- Perforated Louvers

- Checker Plate

- Round Hole Perforated Sheet

- Square Hole Perforated Sheet

- Semi-Circular Hole Metal Sheet

- Triangle Opening Metal Sheet

- Decorative Opening Metal Sheet

Perforated Materials:

- Perforated Sheet in Aluminum Powder Coated Black

- Perforated Metal Plates for Tubes

- Perforated Stainless Steel

- SUS 304 Punched Plate

- Aluminum Perforated Sheet

- Perforated Copper Sheet

- Mild Steel Perforated Metal

Perforated Metal Products

- Perforated Stainless Steel Sheets for Steam Strainers

- Perforated Stainless Steel Sleeves

- Dimple Perforated Sheet Steel Grating

- Stainless Steel Perforated Strainer Basket

- Perforated Stainless Steel Air Curtain Screen

- Perforated Screen Sheet in Stainless Steel

- Perforated Windproof Nets

- Perforated Vent Grille

- Polisher Screen

- Perforated Metal Grader Screen

- Perforated Stainless Steel Milling Screen

- Perforated Angle Bead

- Perforated Plate Sieves

- Slotted Filter Sheet

- Perforated Metal Coils

- Perforated Sheets

- Perforated Panels

- Perforated Metal Screen

- Perforated Steel Tube

- Perforated Filters

- Perforated Grilles

- Speaker Grille

- Perforated SS Tube

- Aluminum Perforated Strips

- Balustrade Panels

- Perforated Panel Railings

- Fire Escape Staircase

- Perforated Rack Panels

- Perforated Architecture Mesh

- Perforated Metal Security Screen

- Perforated Cable Tray

- Perforated Channel Cable Tray

- Checkered Tread Plate

Technical Terms:

- Perforated Metal Opening Patterns

- Applications of Perforated Sheet

- Materials Applied for Perforated Metal

- Benefits of Perforated Metal

- Calculation of Sheet Metal Weight

- Open Area Calculation

- Perforated Metal Definition

- Perforated Metal Features

- Terminology of Perforated Metal

Other Sheet Metals

Processing Machines

Processing

We have expert engineers, complete production equipment and first-class manufacturing technology. We are equipped with the most advanced computer numerical control punching/perforating machines and photo-etching machine to produce perforated net screens in good quality at favorable price. The punching machines can be light, medium-sized, heavy-duty. We supply one-stop perforation services: Laser Cutting, Punching, Shearing, Leveling, Bending, Welding, Surface treatment, Assembly and various fabrications of metal materials.

The metallic materials we work with: iron plate, stainless steel plate, copper plate, aluminum plate, galvanized plate, brass, bronze, nickel silver, composites.

Nonmetallic material: Fibre plate, plastic plate, rubber sheet, film etc.

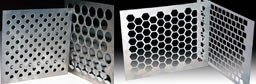

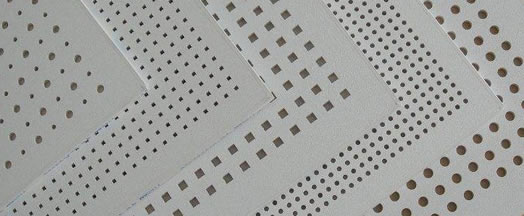

The pattern we can serve: round hole, long round hole, square hole, triangle hole, diamond hole, hexagonal hole, crossed hole, slot, chequer, dimple, embossing, etc.

Processing involved for making of perforated metal products is listed as follows. Our quality control system takes every step in consideration to guarantee the product quality in every step and through the whole process for our customers.

Die: The perforating process starts by designing the precision die. We believe that the quality of the die is critical for the quality of the products. We have therefore invested heavily in the area in recent years and developed our die making techniques.

Perforating: We use the CNC machine to produce state-to-art product. The daily output is over 2000m2, we can perforate the material thickness from 0.1mm to 25mm.

Slitting: Slitting to finished width is done in-line from a coil.

Shearing: Our worker can shear the margins when the tolerance is grater than our in-line process.

Roller Leaving: We can bring the perforated material thickness arranging from 0.8mm to 12mm back to the original flatness with the roller press.

Cleanliness: The perforating process requires the use of lubricants ,and a degreasing step can be applied to cleaning oil free from the material surfaces.

Packaging: The perforated metal usually adopts the form in bulk. We can adopt the packaging, such as cloth, wooden case, and cartons, etc, according to you request. A fairly large number of products can adopt the wooden pallet or steel pallet packaging.

Perforating / Hole Punching

Levelling Step

Light type perforated machine processing

Round Hole Punching

Materials Selected

Storing and Warehouse